Automated Soylent Maker

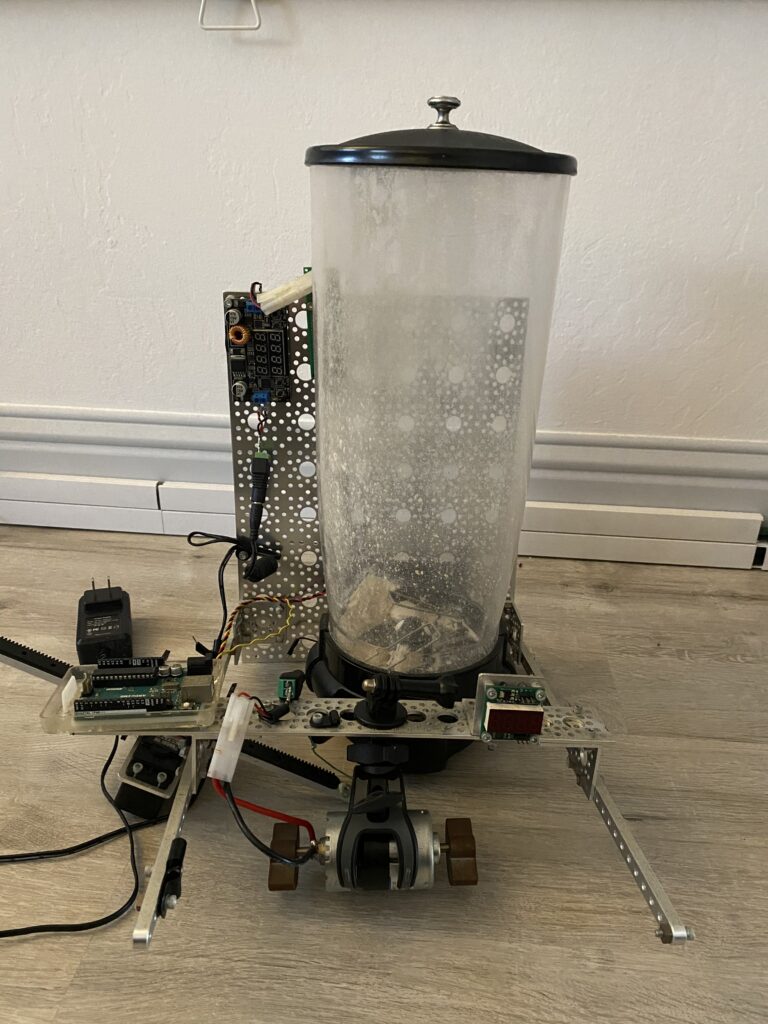

Final Product:

Motivation:

I enjoy drinking Soylent, the popular nutritional replacement drink. It is efficient in terms of money, nutrition, and time to create/consume/clean. I do not enjoy the process of manually making Soylent, which I found myself doing dozens of times per year. This sparked the motivation to automate the process, ideally with an Arduino, which was a new technology I was interested in exploring in 2017.

General Operation:

The moving platform moves the container between the powder dispensing and mixing stations about once per minute, about 15 times, in a process that completes in about 20 minutes. Once the container is filled with water and the process starts, it can proceed unattended and finishes automatically.

Source Code:

The source code for this project is available on Github:

Notice: I deliberately did not invest a lot of time in writing Clean Code because I wanted to focus on other aspects of the project. Be advised Uncle Bob would not look kindly on the above code.

Lower Level Components:

Major Individual Level Components:

- 2x Arduino Uno Rev 3

- 2x HS-785HB Hitec Winch Multi-Turn Servos

- 5 Liter Single Canister Powder Dispenser

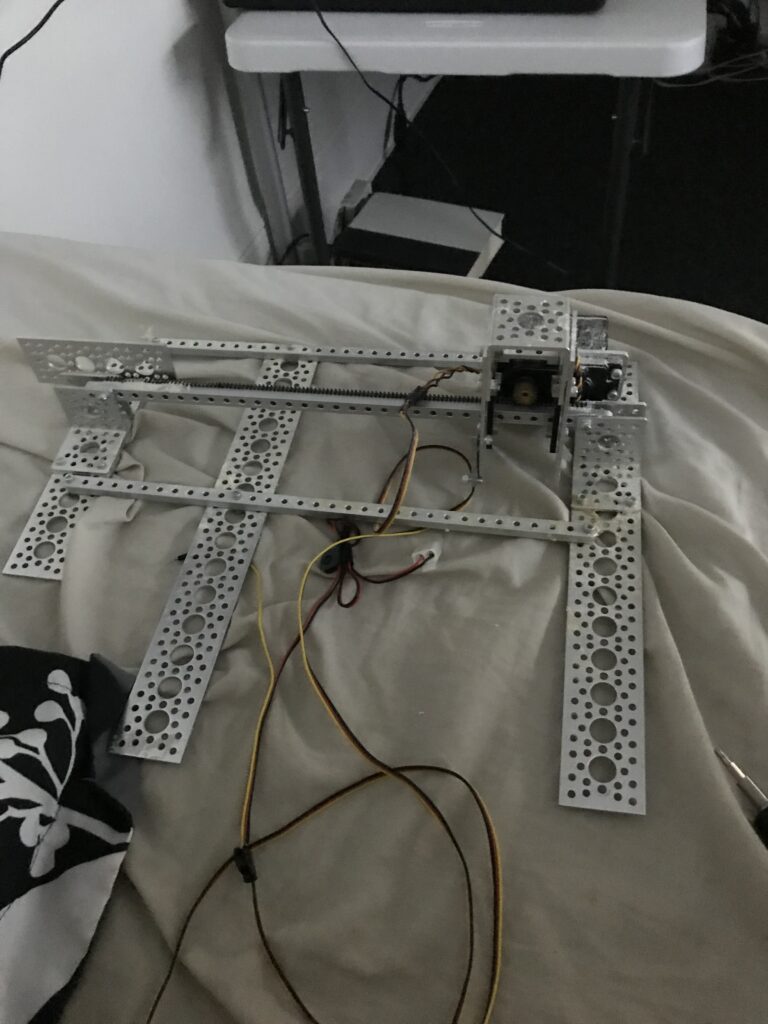

- Various Actobotics Metal Frames for Structure

Lessons Learned the Hard Way

1. Fine Soylent powder had a tendency to clump unexpectedly within the dispenser, causing it to stop dispensing entirely on occasion until I knocked the dispenser unit to break it free. This was eventually resolved by installing a strong mechanical vibrator to automatically clear the clumps. This in turn caused issues keeping the screws in place, as the additional vibration had a tendency to knock them out of their sockets over time.

2. Lining up the blender head and the container reliably and accurately proved surprisingly challenging. It became necessary to put screws on the moving platform so that the container would fall into a specific place each time I placed it there. Lining up the moving platform and blender correctly took many iterations, and I eventually strapped on lasers to the blender head so it was easier to visualize exactly where it would drop down.

3. Dispensing too much powder into the container in a single pass could easily create a situation where the blades became completely covered in powder, and additional dunking/spinning would not clear them. This is the primary motivation for so many passes between powder dispensing and mixing stations.

4. Originally I wanted a station in the middle that would dispense water into the container in the right amount automatically during the start of the process. This was later cut because getting the process to work at all proved more time-consuming than originally expected, partly due to the above lessons as well as a general under-scoping of the project at the outset.